"Students learn in a relaxed setting.

All inclusive.

No previous experienced required."

Welcome

Welcome to the "Sheetmetal Ductwork Fabrication School" which can provide hands on training for a new career and/or improve your existing skills in this specialized custom trade.

| Exciting News for 2020! |

| In addition to our Burkeville,Virginia training site,we now have a 2nd training site in Middletown, New York. Located at 'Quality Heating and Cooling', hosted by owner, Terry Randolph and son Korey. We still offer layout, fabrication and assembly of all types of ductwork fabrications. Classes taught by Jackie Price |

CUSTOM DUCTWORK FABRICATION SCHOOL

Students learn in a relaxed,

non pressure setting. All inclusive. No previous experienced required.

(All photo's on this website are selected from our files of

actual students during their 3 Day

training in the fabrication school workshops)

| Burkeville VA, School Training Date's |

|

2020 Dates are available all 12 months through out the year. Please call 434-603-7827 to reserve/select your 3 days of training. |

| Middletown New York, School Training Date's | |

|

As of now the dates need to be pre-scheduled, listed below are available for

3 days of training:

To see if alternative dates could be made available , speak with Jackie Price. Please call 434-603-7827 to confirm, before completing the registration form. |

|

| April- 04-06-08-2020 | |

| October-10-26-28-2020 | |

fabrication

FABRICATE CUSTOM SHEET METAL

DUCTWORK

Students learn the basic principles of sheet

metal layout/fabrication and proper use of hand tools and machinery..

CONTRACTORS

Tired of having

to pay somebody else for fabricating and installing ductwork? We have

the solutions for your ductwork fabrication.

It is not as difficult or

expensive as you may think, to do it yourself.

Contact me on

434-603-7827 or e-mail me

jgprice47@gmail.com

- About Us - Clients & Testimonials -

-

ABOUT JACKIE PRICE

Over the years, I’ve seen a need to teach the “lost/forgotten art of Sheet Metal layout.” Employers, contractors and most Voc-Tech centers no longer teach the art of Sheet Metal layout. It’s given way to Plasma cutting systems and pre-fab ductwork. I have nothing negative to say about modern technology, but when all else fails; you can always rely on the fundamentals.

FABRICATE CUSTOM SHEET METAL DUCTWORK

Students learn the basic principles of sheet metal layout/ fabrication and proper use of hand tools and machinery..

CONTRACTORS

Tired of having to pay somebody else for fabricating and installing ductwork? We have the solutions for your ductwork fabrication.We now have a generation that has little knowledge of how to make a straight duct, much less custom 'fittings' from a flat sheet. There is an ever increasing need for learning the basic fundamentals. But not all Installations can be 'pre-fabed.'

When an installer performs a 'change out' or 'unit' replacement does the installer know how to design and fabricate the transitions or plenums to connect to the existing supply and returns ducts with the most efficiency and quality? If not, the customer ends up with poor workmanship and probably an underperforming system and the company ends up with a bad reputation. A HVAC system with ductwork that is properly designed, fabricated and sized is the solution to this problem.

I’m passionate about the trade, workmanship and love teaching. I want to pass along my knowledge so that individuals can advance in their career and companies can improve their bottom line.

You will learn in a relaxed, non pressure environment - Don’t hesitate to call if you have any questions or special needs - 434-603-7827

Why Choose Us?

selection of our clients

AJ'S HVAC Alexandria, Virginia

2 time repeating client.

Ted's HVAC, Roxboro, NC.

Absolute Heating and Cooling

Connecticut

Carolina Energy/HVAC Raleigh,NC.

Merck Pharmaceuticals, NJ.

Pine Heating & Cooling, MN.

Stanford University, Ca.

Metro Plumbing & Heating, MD.

IQ Air, Ca.

Bright Star Services, NY.

Quality Heating & Cooling, NY.

AMSEC, Naval Contractor, Va.

Superior Duct Design, NY.

Dillon Construction, W.VA.

Andy's Electrical/Hvac, Fl.

Waldstein Air Serve, Iowa .

Custom Cooling, Hawaii.

Southern Style HVAC, New Orleans La.

Quality Service HVAC/Mechan' Louisa Va.

Bloom Electrical/HVAC, Pa.

California State University, HVAC, Maintenance Dept.Monterey Bay, Ca.

Lockheed Martin Avation HVAC, Michigan

Nelson HVAC, Falls Church, Va.

Dept. Of Homeland security FEMA Sheetmetal Dept. Virginia.selection of our clients

The HVAC GUY Christopher Kerslake, New Jersey.

Air Force Base, San Antonio, Texas.

2 time repeating client.

Johnston Heating and Cooling,

Bedford, Virginia.

Robert B. Payne HVAC Fredericksburg, Virginia, 3 time repeating client.

ICR Service Group, NC.

Alan Construction, Md.

Basnette Plumbing/HVAC, Liitleton, Ma.

Robert Payne HVAC, Fredricksburg, Va.

Honest HVAC, NJ.

QHonest HVAC, NJ.

Costal Carolina Community College, HVAC Program, Jacksonville, NC.

Affordable Service Solutions, Richmond, Kentucky.

Cuyahoga Valley Career Center, HVAC program, Cleveland, Ohio.

ROM-Cooling LLC, Hollywood, FL.

Jones Heating & Energy LLC Albany NY.

Ross Heating & HVAC, Cleveland, Ohio

Raleigh Heating & AC, Raleigh NC.

Complete Comfort AC & Electrical Chillhowie, Va.

Nichols Contracting, Silver Springs, MD.

Golden & Golden AC, Georgia.Testimonials reviews

(Examples from our files)

You may be the last person teaching the "lost Art" of Sheet Metal work. Your knowledge of Sheet Metal fabrication shows in your passion for teaching. I can't wait to use my new skills I've learned here to improve my workmanship. I look at Ductwork as both science and art. I can now make ductwork that my Father would have been proud of.

Chris Kerslake, New JerseyI was skeptical about how much I could possibly learn in 3 days of training. But, Mr. Price proved me wrong! Everyday was jam-packed with training and skill enhancement that I will carry with me for a lifetime! That's not even mentioning the tips of the trade he taught in class. Mr. Price has a true passion for the trade, and there's no doubt that he wants to share it with everyone he can.

Tony Byerly. Air Force, Sam Houston, TexasI am definitely more of a hands on person. I learn better that way. So to me this is the beauty of the lessons you offer. You take out all of the red tape and get straight to what manners.

BobTemple, Southern Style AC, New Orleans, LA. - Classes & Information:

-

CLASSES & INFORMATION

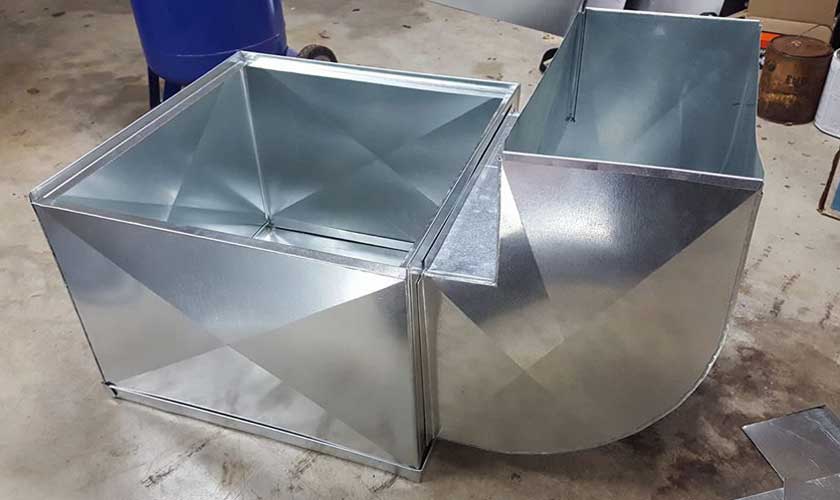

as students you will plan layout, fabricate and install a variety of HVAC ductwork. Such as cleats, straight ducts and caps, elbows, transitions, offsets, plenums, square to rounds and other ductwork as requested. The training will also include fabrication of transitions and plenums for unit replacements and change outs. We still offer layout, fabrication and assembly of all types of ductwork fabrications, plus assembly of ductwork from the CNC Plasma cutter!

Cost: 01-01-2018 Training 3 Day Class $900.00 per person.

Times: Classes meet Monday – Friday 8am to 5pm. Open entry/Open exit. Call -434-603-7827 or E-mail jgprice47@gmail.com to reserve your spot.

Class: Takes about 3 days. Completion times vary depending on student aptitude and prior experience.

Classes: Are open to hobbyist, beginners, apprentices, junior mechanics, mechanics and journeymen.

Lesson: Plans can be developed for all skill/academic levels and requested special fabrications Arrangements can be made for evening and weekend classes. Call for details - 434-603-7827

Lessons: VA. Mr. Jackie Price Sheetmetal Ductwork Fabrication School, 22700 West Colonial Trail Highway, Burkeville, VA 23922

The student will learn the 3 basic principles of Sheet Metal layout: Parallel line development, Radial line development and Triangulation.

See examples below: Sheetmetal Ductwork Fabrication School, Burkeville, VA.

Learning: These basic fundamentals will give the student a general knowledge for fabricating almost any ductwork with practice.

Scott's

Completed Fabrications

Steve's

Completed Fabrications

Doug's

Completed Fabrications

Lessons: NY Mr. Jackie Price Sheetmetal Ductwork Fabrication School, 68 Cottage Street, Middletown, New York 10940

The student will learn the 3 basic principles of Sheet Metal layout: Parallel line development, Radial line development and Triangulation.

See examples below: Sheetmetal Ductwork Fabrication School, Middletown, NY.

Learning: These basic fundamentals will give the student a general knowledge for fabricating almost any ductwork with practice.

- Training

-

Training class Details & Dates

Sheetmetal Ductwork Fabrication School Training Date's Burkeville Virginia: 2019 - Dates available through out the year:

Please call 434-603-7827 to check your requirements, before completing the registration form.Middletown New York: 2019 - As of now the dates listed below are available for 3 days of training:

Please call 434-603-7827 to confirm, before completing the registration form.April: One Class (1) 1st+2nd+3rd July: One Class (1) 22nd+23rd+24th November: One Class (1) 4th+5th+6th Cost: 01-01-2019 Training 3 Day Class $900.00 per person.

This includes all metal, materials, tools and equipment. Upon course completion student will receive a certificate of completion, a picture taken with their completed projects and are allowed to keep all completed duct fabrications.

TRAINING FACILITY:

- Class size: Maximum of 4 students. This allows plenty of time for individual hands on instruction.

- Shop: 40’x30’ shop with four work benches

- Equipment: Pittsburg, Easy edger, 8’ Brake, 4’ Box & Pan Brake, Slitting Shear, 3’ Stomp Shear, Combination Beading machine, Cheek Bender, Spot Welder, English Wheel, Etc

- Hand Tools: Various snips, Awls, Metal markers, squares, Dividers, Rules, Hand Seamers, Etc.

- Requests: Individualized fabrications are welcomed. Call for details.

- Custom Fabrications: Individual and company orders are accepted.

HAVE SNIPS WILL TRAVEL:

- On Site Training: Onsite training is available for companies and Individuals. Call -434-603-7827 or E-mail jgprice47@gmail.com

'OSHA' - SAFETY REGULATIONS:

- OSHA: Safety regulations are practiced at all times.

- Safety: Is Job # 1.

- Prohibited: NO DRUGS or ALCOHOL on site.

INSTRUCTOR - TYPICAL LESSON PLAN: STRAIGHT DUCT:

- Objective: The student will make a 6” x 4” x 8” long sheet metal rectangular straight duct

- 56789

- Purpose: Straight duct is normally square or

rectangular in shape fabricated in specific sizes and lengths based

on system

design specifications for the transfer of air in Heating and Cooling systems. - Materials Required: 28 galvanized sheet metal, cut 21-1/4” x 8”

- Learning Materials: blueprint, Sheet metal textbook, handouts, and Instructor demonstrations.

LAYOUT-FABRICATION-ASSEMBLY INSTRUCTIONS:

- Review blueprint: read chapter 4 sheet metal textbook (straight duct) consult with Instructor.

- Observed Instructor’s: safe demonstration and operation of 4’ stomp shear.

- Cut: sheet metal to correct size on 4’stomp shear 21-1/4” x 8” while being observed by instructor

- Place: cut metal on workbench and check for square corners.

- Mark: layout lines starting in lower left hand

corner with metal marker and framing square according to straight

duct blueprint.

Consult with Instructor for demonstration. - Double check: all layout lines for accuracy. Have Instructor give final check for accuracy.

- Read page 63: in sheet metal textbook on Pittsburg

seam and observe Instructor demonstration on safety and operation

of

Pittsburg machine. Student will form Pittsburg seam. - Read page 42: in sheet metal textbook on 8’ brake and observe Instructor on safety and operation.

- Bend: straight duct at 90 degree angles from marked bend lines on 8’ brake.

- Close: and hammer Pittsburg seam with riveting hammer according to Instructor demonstration.

- Turn ½”: drive cleat edges with folding tool on narrow 4”side of straight duct as Instructor demonstrates.

- Have instructor: grade and check your completed straight duct and cleanup work area and return tools.

- Criteria for Completion: 6” x 4” x 8” long

straight duct will be square with smooth Pittsburg seam. No sharp,

jagged edges and

within a 1/16” +/- tolerance.

- Registration Form & Payments:

-

registration form & payment

Pre-Registration:

1) Before completing your registration form, telephone 434-603-7827 to pre-arrange - confirm course dates, school location and payment details.

2) Please note that the registration Fee is a 'Non Refundable' payment and required to confirm your booking.

3) If problems occur, such as illness, change of dates, or student withdraws please call 434-603-7827 to arrange alternative dates.

4) Please ensure that you make your payment via PayPal before submitting your Registration Form!Burkeville VA, School Training Date's 2019 Dates are available all 12 months through out the year.

Please call 434-603-7827 to reserve/select your 3 days of training.

Middletown New York, School Training Date's As of now the dates need to be pre-scheduled, listed below are available for 3 days of training:

To see if alternative dates could be made available , speak with Jackie Price.

Please call 434-603-7827 to confirm, before completing the registration form.April: One Class (1) 1st+2nd+3rd July: One Class (1) 22nd+23rd+24th November: One Class (1) 4th+5th+6th

Registration: On-Line Form

Option if you wish to mail your form - Click here to open and print

Payment: Secure encripted payment via PayPal

Before Submiting the above registration form, please telephone 434-603-7827 to confirm course dates, school location and payment details.

Enter Alternative Pre-Agreed Payment Amount

- Gallery:

-

Gallery

Welcome to our students photo gallery.

Yes, these photo's are selection taken from our files of actual students during their 3 Day training in the fabrication school workshop.

Contact Us - Lodging - location

Addresses:

Sheetmetal Ductwork Fabrication

School

22700 West Colonial Trail Highway, Burkeville,

VA 23922

Sheetmetal Ductwork Fabrication School,

68

Cottage Street, Middletown, New York 10940

Contact -Telephone:

Mr. Jackie Price - 434-603-7827 (Office)

Contact - E-mail:

Mr. Jackie Price - jgprice47@gmail.com

Website Domain:

Quick Link Domain: www.smdwfs.com

Registered Domain Name:

https://www.sheetmetalductworkfaricationschool.com

Local Area Lodging: Burkeville VA

Quality Inn,

2.2 miles

from Sheetmetal Ductwork Fabrication School

Reservation Telephone:

434-767-3750 Link to:

Website

Quality Inn, 2108 S. Main St, Farmville, VA.

10.3 miles

from Sheetmetal Ductwork Fabrication School

Reservation Telephone:

520-433-4615 Link to:

Website

Super 8 Hotel 2012 S. Main Street, Farmville, VA.

10.4 miles

from Sheetmetal Ductwork Fabrication School

Reservation Telephone:

434-414-1903 Link to:

Website

Days Inn, 2015 S. Main Street Farmville, VA.

10. 3 miles from Sheetmetal Ductwork Fabrication School

Reservation Telephone:

844-212-8398 Link to:

Website

Tru By Hilton, 1913 South Main Street, Farmville, VA

10.8 miles

from Sheetmetal Ductwork Fabrication School

Prefer to call:

Telephone: 877-214-6725 Link to:

Website

Contact Form: VA & NY

Find us: Burkeville VA

1-1/2 miles West 460 from Burkeville, Va - Driveway entrance on the right, with sign

11 miles East 460 from Farmville, Va. Driveway entrance on the left, with sign.

Local Area Lodging: Middletown NY

Microtel Inn and Suites

19 Crystal Run Crossing,

Middletown, NY.

845-243-6040

5 miles from training

site

Reservation Telephone:

800-337-0050

Link to:

Website

Hampton Inn

20 Crystal Run Crossing, Middletown,

NY.

845-344-3400

5 miles from training site

Reservation

Telephone: 844-219-8501

Link

to:

Website

Courtyard by Marriott

24 Crystal Run Crossing,

Middletown, NY.

845-695-0606

5 miles from training

site

Reservation Telephone:

888-236-2427

Link to:

Website

Days Inn

4939, Route 17, New Hampton, NY.

845-374-2411

11

miles from training site

Reservation Telephone:

800-225-3297

Link to:

Website

Find us: Middletown New York

TRAVEL BY:

Air: Stewart International airport, Newburg, New

York

Tel: 845-838-8200

Link to Website 20 miles from training site.

Rail: Train Service, New York City to Middletown, New York

Link to Citymetro Website Link to NY/Middletown

Website

2 blocks from training site.